STAAT MOD [2020 DIRTT Healthcare Project of the Year]

Services Provided

- Modular interior construction

- Design services

- Logistics and project management support

The Challenge

Capacity needed stat.

In the wake of COVID-19, healthcare facilities across North America were pushed to capacity and beyond. The end-user, a Hospital in Lawrenceville, Georgia, sits in the northeastern suburbs of Atlanta, Georgia, where Covid levels have remained a “red zone” for much of the Covid-19 pandemic.

“The Atlanta region is experiencing rapid growth, and, even before the COVID-19 pandemic, we began looking at opportunities to increase our bed capacity and flexibility to handle an influx of patients,” said Debbie Mitcham, CEO of end-user. With a seemingly unending surge of Covid patients adding to an already stressed workload, the hospital needed to add to its capacity as quickly as possible. Lives were on the line.

The Solution

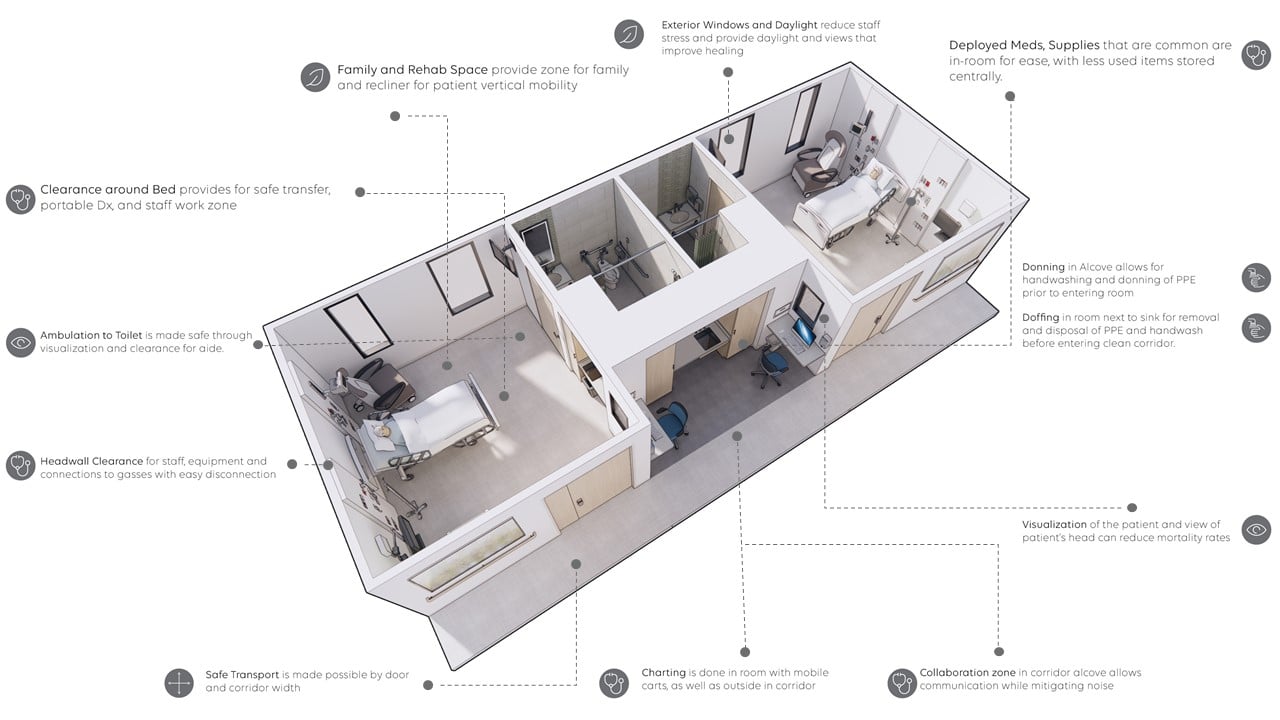

As the first hospital in the Southeast to install STAAT Mod (Strategic, Temporary, Acuity-Adaptable Treatment) units to care for COVID-19 patients, Northside is fulfilling a much-needed remedy in their patient capacity. The innovative and highly engineered STAAT MOD concept conforms to hospital quality standards and easily flexes to provide traditional inpatient capacity or critical care. STAAT MOD operations allow for Airborne Infection Isolation Rooms (AIIR) that provide increased safety for both patients and caregivers. The acuity-adaptable rooms installed at Northside are a mix of critical care ICU, AIIR, and lower acuity spaces such as Step Down, Medical-Surgical, and Observation rooms.

The STAAT Mod has an excellent life span, making it durable enough to support a longer-term hospital strategy, and is fully code compliant. The added space allows Northside to care for various patients without sacrificing clinical quality, safety, efficiency, or any patient’s dignity.

For Lerdahl, the project results are genuinely astonishing and rewarding. A 71-bed modular hospital, designed and built in a matter of weeks. This type of high acuity project would typically take many months, if not years. This project serves the immediate need to treat patients during a pandemic and has become the foundation for a robust modular partnership with a top-ranked General Contractor.

STAAT Mod, a volumetric hybrid modular solution, incorporates DIRTT solutions for the interior build-out of a steel frame box designed to fit on the back of a semi-truck and moved from the contractor’s fabrication shop to wherever the hospital location may be (in this case, about 900 miles).

Components include walls, door frames, millwork, flex gas, power, and networks.

- DIRTT walls in 45,000SF projects

- 600 LF millwork

- 420 Medical Gas Drops, utilizing DIRTT’s flex hose system

- Full modular Power and Networks

These Critical Care patient units met Airborne Infection requirements, FGI Guidelines, and local code requirements.

Debbie Mitcham remarked that “in less than four months, we’ve been able to do what would normally take us 15 months, and this investment enables us to provide a quality and a durable solution to serve our community throughout the uncertain curve of this infection.”

“This became more than a project,” stated Christina Robotka, DIRTT Healthcare Specialist for Lerdahl. “It grew into a mission to hone our expertise in modular construction to passionately support saving lives during a pandemic. Seeing the capability of a full modular healthcare opportunity comes to fruition is truly rewarding.”

“Within a few short months, we had a 71-bed unit fully operational and ready to go. We need only weeks or months to fabricate, ship, install and operationalize several inpatient wings. To build a new hospital would take years.”